Customization

Optimized & industry-ready solutions

for forming special concrete elements

Safe working conditions proviSteel forms which are produced at customer’s request, mainly used for forming concrete elements with special or non-standard shapes, in projects where conventional systems are not applicable or difficult to use by systems safe equipment.

Salesbridges custom-made steel formwork especially suitable for forming:

- Bridge pylons

- Concrete elements with curved surfaces in several directions

- Pre-cast concrete elements as bridge girders, columns etc.

Our custom-made steel formwork reduces time for preparing and assembling of the forms at a construction site, provides exactly required geometrical shape of a structure formed and has high load-bearing capacity, comparing to site-made forms.

Load-bearing capacity:

- The system can be customized to withstand almost any load of fresh concrete.

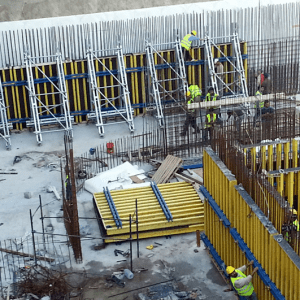

SHOWCASE

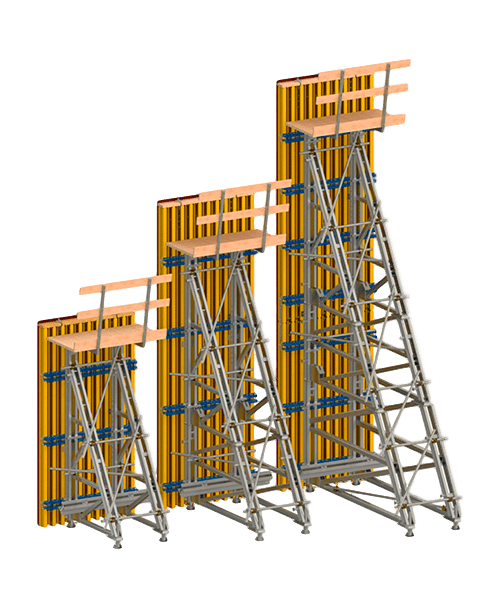

The system of modular supporting frames by Variant is used for single-sided walls forming such as retaining walls, dam walls etc. Shear forces which appear on the formwork shutters owing to fresh concrete pressure, are held and redistributed on the base by means of modular supporting frames and diagonal anchors. Single-sided supporting system allows walls with the required pouring-height up to 8,00 m to be formed.

Load-bearing capacity:

Owing to its load-bearing flexibility, the Single-sided modular supporting system can be assembled and customized for different pressure of fresh concrete required, up to 50 kN/m2.

Areas of use of the single-sided modular supporting system:

- Retaining walls;

- Dam walls;

- Stop-ends of walls and slabs with large thickness;

- Walls of great thickness, in this case single-sided system is to be installed on both sides;

- Walls where there is no place for installation of opposite formwork shutter (double-sided system).

System adaptability:

- Flexible height adjustment;

- Easily combines with Variant’s wall systems, such as, framed formwork Varimax and large-area formwork Vertex 60;

- Rapid adaptation to any unevenness of the ground in an installation area;

- Can be used for special application. (e.g. positioned horizontally and anchored to the structure used as heavy-duty working platforms).

Cost-effective;

- Can be repositioned by use of wheel units, in order to save crane time;

- Large areas of single-sided wall can be easily cast;

- High number of use cycles means lower follow-up expenses;

- Reduction of expenses by means of system adaptability;

- Galvanized steel frames, for long service life.

Easy handling and planning;

- All the connectors and accessories are easily fixed into the slots and quickly tighten, consequently forming time is efficient and maximized;

- Any requirements for architectural concrete design can be met.

Safe use

- Accessories such as — wall brackets makes for save and easier handling of the system.